Value engineering refers to a systematic process aimed at increasing the value of a product. It focuses on improving functionality while keeping costs low. Sometimes referred to as “value analysis,” value engineering involves a team of designers and engineers coming together to analyze every step of a project to ensure maximum value.

When it comes to construction projects, value engineering can be an extremely valuable process for all stakeholders, especially if done in the beginning. Though it can be applied during any phase of the design process, applying the methodology early will save time and costs down the line, providing a better return on investment.

The Society of American Value Engineers (SAVE) defines value as a function divided by cost. The function is what the product or service does, and cost refers to the components needed to construct it.

The history of value engineering dates back to WWII, starting at General Electric Co. During the war, there was a shortage of labor, raw materials, and component parts, forcing engineers like Lawrence Miles and Henry Erlicher to explore alternatives. As a result, they discovered alternative materials and resources that would reduce costs while still maintaining quality.

Low and behold, the concept and systematic approach of value engineering were born. Implementing VE in construction can provide the best possible value for a project’s life cycle. It’s all about finding that sweet spot where low cost meets high value.

The Stages of Value Engineering

The value engineering process is broken up into three stages: planning, design and methodology, and approach.

Planning Stage

The planning stage is the earliest aspect of development and is an important part of maintaining solid communication in construction projects. Starting your project with a plan is beneficial so that there are fewer changes and redesigns down the line that could affect the overall schedule, cost, and design plans.

Here is what you can expect in this phase of development:

- Defining key goals, objectives, and criteria for the project

- Functional analysis of the facility

- Review of all utility and material options

- A projected budget for the project

- Ideation of alternative and sustainable solutions

Since this is the planning phase, it provides the value engineering team time to assess all possible options for the project to ensure the best value. It also provides the team with a better understanding of what the desired function of the project will be.

Design Stage

During the design stage, all parties come together to review the projected design plan.

The VE team will usually conduct a workshop during this stage. The purpose of the workshop is to review all of the project elements such as the design plans, estimated costs, projected timeline, and the best value options.

Contrary to the planning stage, the design stage is aimed at reviewing the initial findings and providing the client with all possible alternatives.

Methodology Stage

The last and final stage is the methodology stage, which is broken up into six important steps.

Each step involves critical analysis and elimination to come to a solid understanding of what alternatives are going to be best.

1. Gather Information

The information phase is aimed at gathering all data needed to understand the full scope of the project.

This is the time to evaluate and define the owner objectives, materials needed, scheduling, cost, and formal design. The team of engineers can gather information from similar projects to compare all possible options.

2. Function Analysis

The two types of functions that are analyzed in this phase are the primary and secondary functions.

The primary function is the core of the project and holds the greatest value. It represents what is required to make the product work. The secondary functions don’t hold as much value but are always worth noting. The functions are always presented as verb-noun combinations.

For example, if a team was building a bridge and needed to determine the function, the basic or primary function of that bridge would be the “cross barrier.” In simple terms, a bridge is needed to get from point A to point B.

Once the functions of the project are determined, the team can move on to the creative phase where they can start brainstorming solutions.

3. Creative Brainstorming

This phase, also known as the speculation phase, involves the team coming up with creative ideas for the project’s function. These ideas should be related to the information that was gathered during the function analysis and focused on lowering initial costs and increasing value.

The brainstorming session allows the team to assess all solutions while also evaluating any functions that were previously in place.

All aspects of the construction project’s lifespan should be considered. Safety of the project, environmental factors, materials and tools needed, considerations for the type of foundation, analyzing the construction site, and other important details should not be overlooked.

The team will generate as many ideas as possible before moving on to the evaluation and analysis phase. Quantity is favored over quality during brainstorming — the more ideas, the better. Team members can combine ideas and build upon each other’s findings before they’re further evaluated.

4. Evaluation and Analysis

After the team comes up with specific criteria for evaluation, they will then thoroughly vet all ideas, highlight the advantages and disadvantages of each, and rank which alternative solutions they think will be best.

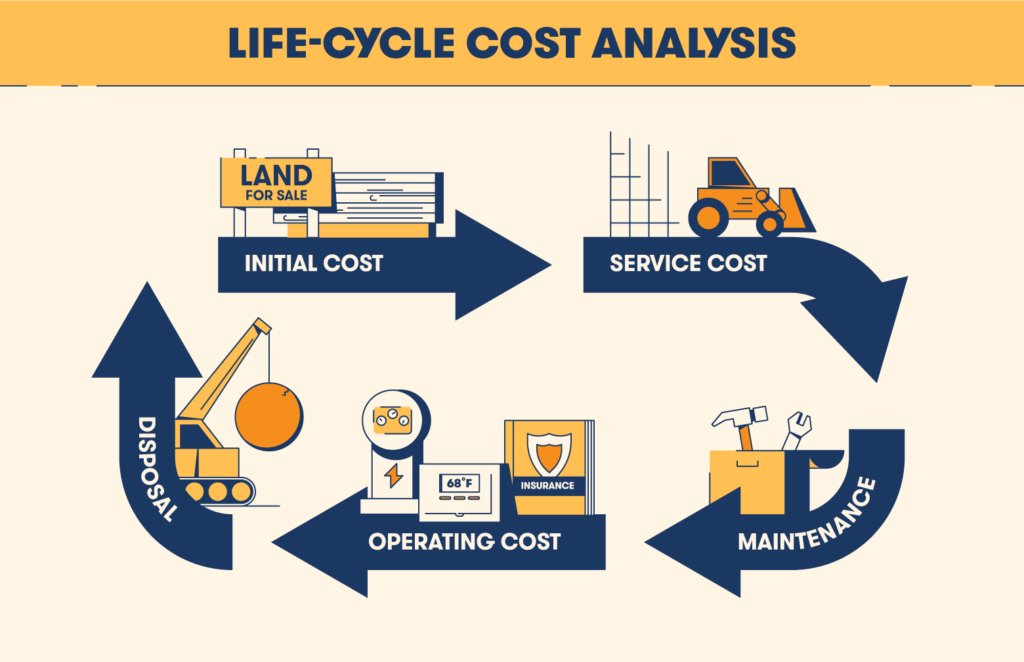

It’s also important to conduct a life-cycle analysis during this phase. This is where you consider all costs at every phase, from initial construction costs such as materials, land acquisition, and construction equipment, to long-term development costs, like energy and water.

The team will assess different alternative solutions that may cost them more now but less down the line or vice versa. Looking at the project’s life cycle will determine the ideal solution as far as cost is concerned.

For example, as will look at the longevity of an infrastructure type and take into account the systems and materials needed to maintain the building far beyond the initial build. This could be something like energy efficiency. It might cost more in the initial phases, but looking at the lifespan of the building, it will cost less overall.

Cost estimate databases like RSMeans data’s construction cost estimator are helpful when projecting exact costs.

All ineligible ideas will be discarded and will no longer need further analysis. The process of elimination is key to narrowing down and determining what alternatives are going to be brought into the next phases.

5. Project Development

The development phase is where the team picks the best alternatives thus far. Once the ideas passed the evaluation phase, the team will then establish those ideas into a written and verbal proposal that will be presented in the final stage of the project.

Each recommendation will outline the pros and cons of the proposed solution, and include cost comparisons, sketches and design models, projected timeline and other necessary information that will be helpful to the client.

A comparison of the original design method will also be presented if there was some sort of change.

6. Presentation and Briefing

During the last phase, the team will present their findings and recommendations to all stakeholders and decision-makers. This formal presentation acts as an opportunity to explore the final possible alternatives and determine which value proposal will be best suited for the project moving forward.

The purpose of this stage is to obtain approval for the project.

Construction Stage

Once the three stages of value engineering are complete, the construction stage begins. Though this is not always a phase that VEs get involved in, it is still possible to implement value engineering in this stage through Value Engineering Change (VEC) Proposals.

This type of proposal is made by construction contractors, as they can assess the design plan using their experience and expertise. It’s common for changes to occur during this stage, though implementing VE this late can be risky. It’s typically recommended to start all value engineering procedures before any construction contracts are signed.

The contractor would then provide any additional solutions that could enhance the value of the project. This can be beneficial because it provides the project with a fresh look and opinion from the contractor’s point of view.

The Future of Value Engineering

Value engineering isn’t just an essential part of the construction. This methodology system can and has been applied in many different industries. Every process, whether that be building out a particular product or creating a new service, has a function, and value engineering can be applied to solve any problem associated with the process.

In today’s world, new and improved technologies and resources are always being discovered, which broadens the available options for solutions. The construction industry is known for its ability to adapt to current trends and technological advancements.

Not only does value engineering provide monetary benefits, but it also affords all participants the opportunity to get creative and explore a myriad of findings to maximize functionality. If done properly, it should improve a project’s performance while reducing total costs.

Consider applying this methodology to your next construction project by hiring a value engineering team or acquiring the necessary skills and becoming certified through SAVE International’s certification program.

Seeing a project through from start to finish using value engineering will produce the best quality product and optimum value for the client.